Straight Line Bead in Vertical position(3F) on an M.S. plate. Arc welding

WELDING PRACTICAL

|

| Straight Line Bead in Vertical position |

The recommended welding technique for creating a straight line bead in a vertical position on an M.S. plate Arc welding is to use the uphill or upward progression technique.

Aim:-To make a Straight Line Bed in a Vertical position(3F) on an M.S. plate.

Tools and pieces of equipment:- Welding set, Power supply, Power source, workpiece, lead, electrode, the electrode –holder, Welding table, earth clamp.steel wire brush, gloves, tong, flat file, scriber, bench vice, steel rule, trysquare, chipping hammer, goggles.

Raw Material:- M.S. Flate 10mm. Thickness and Electrode of 3.15mm.

Straight Line Bead in Vertical Position Procedure:-

1. Take the two M.S. pieces of the given dimensions and clean the surfaces thoroughly from rust and dust remove the sharp corners and burns by filling and preparing the workpiece.

2. The workpieces are positioned on the welding table from a vertical position on the welding table to a straight line bead.

3. Switch on the power supply.

4. Switch on the MCB of the power source welding machine.

5. Join the work lead to the –ve terminal.

6. Select the electrode 3.15mm.

7. The electrode is fitted into the electrode holder and the welding current is set to a proper value.

5. The ground clamp is fastened to the welding table the machine is switched on.

6. The arc is struck and the workpieces are welded at the ends of both sides.

7. The alignment of the lap joint is checked and the tack welded pieces are resting if required.

8. The Earth clamp is fixed on the welding table.

8. The arc is Striking on the workpiece.

9. The alignment to the corner joint and checked and the tack welded pieces are resting it required.

10. Remove the slag, and spatters, and clean the joint.

11. Filing is done to remove spatters around the weld.

Safety:-

1. Obey PPE (Personal Protective Equipment).2. Work as per instructions.

3. Keep yourself away from the fumes.

4. Check the welding cables.

5. Wear proper clothing.

6. Use a hand screen while welding.

7. Check for electric sparks while welding.

8. Observed the welding place after the welding of 30min.

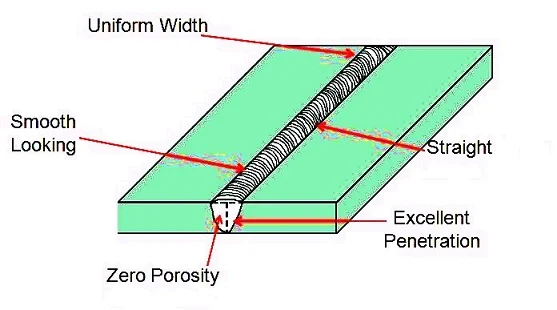

Result:- The straight-line bead in a vertical position is made using the Tools and equipment mentioned above.

0 Comments

Leave a Reply...