Welding Transformer Single-stage works on the Principle.

|

| Welding Transformer |

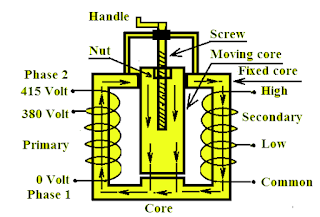

Introduction: - Welding transformers are available. Single-stage light duty for small fabric manufacturing for large-scale industrial work.

Single-phase transformers are lighter in weight and are

typically rated for a 200 A welding current. There are some taps in the

secondary winding for varying current, such as 100, 125, 150, etc. These

transformers operate on a 230-volt single-phase supply.

Four heavy-duty use transformers of high rating come in

different sizes. Thes transformer's input supply voltage is two-phase 400 volts.

The output current rating is 300 to 600 Amps. The output side common, low, and

high are three points. The common ground is connected and the welding lead is

connected to low for 300 amperes current and high for 300 to 600 amperes current.

The open-circuit out voltage of the welding transformer is about 90 volts, while

it reduces to 50-60 volts during welding. The primary and secondary winding

uses strip conductors for winding. The primary winding is tapped for a

connection of 380 volts or 415 volts by a jumper strip setting.

Current Adjustment System

When the supply is delivered to

the primary winding, it generates an alternating current in the core. Secondary

winding that is wound on the same core linkage as the flux that is produced

by the primary winding. So the voltage is induced in the secondary winding, and

he,nce the welding current is used when welding. S,o to control the current, we have to

control the flux linkage of the secondary winding.

For that, a bypass magnetic path is provided for the flux

with the help of an adjustable magnetic core as shown in the diagram. This core

passes the magnetic flux, so the flux linkage decreases with the secondary

winding, which controls the output current. This adjustable magnetic core slides

down the middle of the main core with the help of the current control handle.

⚡ वेल्डिंग ट्रांसफॉर्मर कैसे काम करता है?

वेल्डिंग ट्रांसफॉर्मर AC सप्लाई को लो वोल्टेज और हाई करंट में बदल देता है। इसका मुख्य उद्देश्य एक ऐसा करेंट देना है जिससे धातु का मेल्टिंग पॉइंट पार किया जा सके और दो धातुओं को मजबूती से जोड़ा जा सके।

🔁 Basic Principle:

वेल्डिंग ट्रांसफॉर्मर विद्युत चुम्बकीय प्रेरण (Electromagnetic Induction) के सिद्धांत पर काम करता है।

Primary Coil में AC करंट दिया जाता है, जिससे Secondary Coil में कम वोल्टेज और ज्यादा करंट उत्पन्न होता है।

🔥 वेल्डिंग वास्तव में क्या है?

वेल्डिंग एक प्रक्रिया है जिसमें दो मेटल्स को इतनी ज्यादा गर्मी दी जाती है कि वो मेल्ट होकर आपस में जुड़ जाते हैं।

💥 असल में, वेल्ड एक पर्मानेंट जॉइंट होता है, जो इतना मजबूत होता है कि वो मेटल की मूल संरचना से भी ज्यादा टिकाऊ हो सकता है।

🧲 वेल्डिंग ट्रांसफॉर्मर के मुख्य भाग:

| भाग का नाम | कार्य |

|---|---|

| 🌀 Primary Coil | हाई वोल्टेज AC लेती है |

| 🔄 Core | मैग्नेटिक फ्लक्स को गाइड करता है |

| ⚙️ Secondary Coil | कम वोल्टेज, हाई करंट पैदा करता है |

| 🔌 Output Terminal | इलेक्ट्रोड होल्डर से जुड़ता है |

⚙️ उपयोग कहां होता है?

🔧 वेल्डिंग ट्रांसफॉर्मर का उपयोग मुख्यतः निम्नलिखित क्षेत्रों में किया जाता है:

-

🏗️ कंस्ट्रक्शन इंडस्ट्री

-

🚗 ऑटोमोबाइल रिपेयरिंग

-

🛠️ मैन्युफैक्चरिंग यूनिट्स

-

🏭 हेवी इंडस्ट्री

✅ वेल्डिंग ट्रांसफॉर्मर के फायदे:

✨ सिंपल डिज़ाइन

⚡ हाई करंट कैपेबिलिटी

🔌 कम मेंटेनेंस

💸 कम लागत

❓ क्या आप जानते हैं?

📚 Welding is not just about heat!

वेल्डिंग केवल गर्मी नहीं, बल्कि दबाव और इलेक्ट्रिक करंट के सही संतुलन से बनती है।

0 Comments

Leave a Reply...