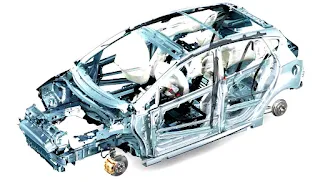

Maruti cars used for welding Process

|

| Maruti cars |

There are 35 different welding and Maruti cars used

processes.What type of welding is used in maruti suzuki

1) Gas welding.

a) Air-acetylene welding | b) | Oxy-acetylene welding |

c) Oxy-hydrogen welding | d) | Pressure gas welding |

2) Arc welding. | ||

a) Carbon Arc welding | b) | Shielded metal arc welding |

c) Submerged arc welding | d) | Tig welding |

e) Mig welding | f) | Electroslag, Electrogas welding |

3) Resistance welding. | ||

a) Spot welding | ||

b) Projection welding | ||

c) Flash butt welding | ||

4) Solid-state welding | ||

a) Cold welding | b) | Diffusion welding |

c) Explosive welding | d) | Ultrasonic welding |

5) Thermo - Chemical welding process.

6) Radiant energy welding process.

Advantages of welding

a) A good weld is as strong as the base metal.

b) General welding equipment is not very costly.

c) Portable welding equipment is available.

d) Welding permits considerable freedom in design.

A disadvantage of welding

a) Welding gives out harmful radiations, fumes, and spatters.

b) Welding results in residual stresses and distortion of the w/p.

c) Jigs and fixtures are generally required to hold and position the parts to be welded.

d) A skilled worker is a must to produce a good welding job.

Practical Application of Welding

1) Aircraft construction.

2) Automobile construction.

3) Bridge.

4) Building.

5) Pressure vessels and Tanks.

6) Railroad equipment s.

0 Comments

Leave a Reply...