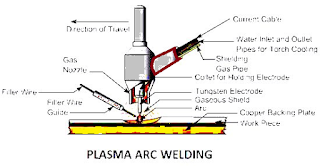

Plasma ARC Welding Basics

Plasma arc welding is an arc welding process wherein coalescence is produced by the heat obtained from a constricted arc set up between a tungsten electrode and the water-coded nozzle. The process employs two inert gases one forms the arc plasma and 2nd shields the arc plasma.

Plasma Arc Welding Working

A Plasma is a gas that is heated to an extremely high

temperature and ionized so that it becomes electrically conductive, the plasma

arc welding process uses this plasma to transfer an electric arc to a w/p. The

metal to be welded is melted by the intense heat of the arc and fuses together.

In the plasma welding torch a tungsten electrode is located

within a copper nozzle having a small opening at a tip. A pilot arc is initiated between the torch electrode and the

nozzle tip. This arc is then transferred to metal to be welded. By forcing the plasma gas and arc through a constricted orifice, the torch delivers a high concentration of heat to a small area. The

energy of the plasma

jet and thus the temperature is dependent upon the electrical power employed to create arc plasma. A typical value of temperature

obtained in a plasma jet torch

may be of the order of 50,0000F as against 10,0000F in ordinary electric

welding. arc.

Plasma Arc Welding

Construction:

A direct current power source having dropping characteristics and an open-circuit voltage of 70 V is suitable for plasma arc welding. A current of 50 to 350 Amp, a voltage of 27 to 37 volts, and a gas flow rate of 2 to 40 lit/min are required.

High-frequency generators and current limiting resistors are

used for arc ignition.

A plasma torch is either water-cooled increases the life of the nozzle and the electrode. Shielding

gases, two inert gases, or gas mixtures are employed. The orifice gas at lower

pressure and flow rates forms an arc

plasma. The pressure of the orifice gas is intentionally kept low to avoid weld metal turbulence, but this low pressure is not able to provide proper shielding of the weld pool. To have suitable shielding protection, the same or another shielding gas is sent through the outer shielding ring of the torch at a comparatively high flow rate.

Plasma Arc Welding Advantages

1) Stability

of ARC.

5) Plasma arc

welding can produce radiography quality welding at high speed.

Plasma Arc Welding Disadvantages

1) Infrared and ultraviolet radiations necessitate special protection devices.

2) Welder needs earplugs because of unpleasant disturbing and damaging noise.

3) More

chances of electrical hazards are associated with this process.

Plasma Arc Welding Application

1) In

tube mill application.

2) Welding cryogenic, aerospace, and high-temperature

corrosion-resistant alloys.

3) Nuclear

submarine pipe system.

0 Comments

Leave a Reply...