|

| Explosive welding |

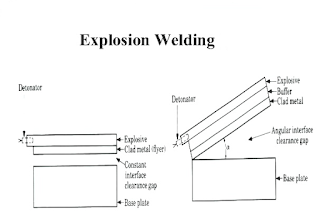

Explosive welding is a solid-state welding process where the joint is affected by the high-velocity movement produced by a controlled detonation.

Explosive Welding Construction:

Explosive welding is used primarily for bonding sheets

of corrosion-resistant metal to heavier plates of base metal (a cladding

operation), particularly

when large areas are involved. The principles of explosive

welding have been schematically illustrated in Fig. The bottom sheet

or plate is positioned on a rigid base or anvil and the top sheet is

inclined to it with a small open-angle between

the surfaces to be joined. An explosive material, usually

in the form of a sheet, is placed on top of the two layers of

metals and detonated progressively, beginning from the mating

surfaces. Compressive stress waves, of the order of thousands of Mega

Pascals, sweep across the surface of the plates. Surface films are liquefied

or scared of the metals and are jetted out of the

interface. The clean metal surfaces are then thrust together

under high contact pressure. The result is a low-temperature weld with an

interface configuration consisting of a series of interlocking ripples.

The bond strength is quite high and explosive

clad plates can be subjected to a wide variety of subsequent processing,

including further reduction in thickness by rolling. In this

solid-state welding process, numerous combinations of dissimilar metals can be joined.

Explosive Welding Working :

The flyer plate is to be joined with the parent plate. There is a

buffer above the flyer plate which may be of rubber. Cardboard

or similar material to protect the surface of the flyer plate from

damage. Above the buffer is a layer of explosive which is detonated from the lower

edge.

As the explosives ignited, the detonation wave front progresses across

the surface of the flyer plate in a straightforward and uncomplicated manner. The

explosive impulse provides both extremely high normal pressure and a slight,

relatively sliding pressure between the flyer plate and the parent

plate. At the point of impact, S as shown in fig, high instantaneous pressure is

generated which is large compared with the shear

strength of the materials.

explosive welding advantages and disadvantages

Advantages of explosive welding

1) The simplicity of the process.

2) Extremely largesurface can be bonded.

3) Welds can be produced on heat-treated metals without

affecting their microstructure.

4) Thin foils can be bonded to a heavier plate.

5) Explosive bonds have a solid-state joint that is free

from the heat-affected zone.

6) Luck of porosity, phase change, and structural

changes impart better mechanical properties to the joint.

Explosive Welding Limitations

In industrial areas, the use of explosives will be

severely restricted by the noise and ground vibrations caused by the explosion.

1) The regulations relating to the storage of explosives and the problem

of preventing them from falling into unauthorized hands may well prove to

be the main obstacle to the use of explosive welding.

2) Metal thickness greater than 62 mm of each alloy

cannot be joined easily and required high explosive loads.

3) Materials such as beryllium, tungsten boron, glass,

and ceramics are not normally processed by explosive welding.

Explosive Welding Applications

1) Many dissimilar metals

combinations have been joined successfully with the help of explosive

welding.

2) Strong metallurgical bonds can be

produced between metal combinations that can not be welded by other processes.

3) Pipes and tubes up to the 1.5-meter length

have been clad with this process.

4) In critical space and nuclear applications, explosive

welding permits the fabrication of structures that cannot be made by other means.

5) Major areas of use of explosively clad products are heat exchange tube

sheets and pressure vessels.

6) Explosive cladding is finding use in the die-casting industry for nozzles,

die-cast biscuits, and other components.

7) Explosive welding has been used for the plugging

of nuclear heat exchanges.

8) Metal/metal wire composite materials have been fabricated using explosives

welding.

0 Comments

Leave a Reply...