FCAW welding process flux-cored arc fastening electrodes

|

| FCAW |

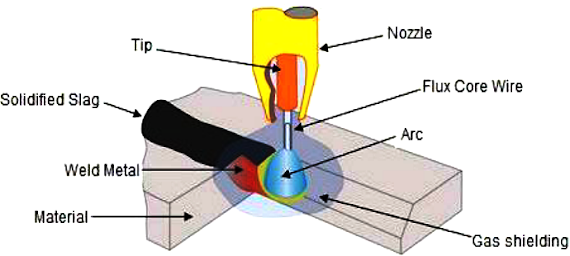

FCAW welding process: the electrodes employed in flux-cored arc fastening square measure fabricated from a flux core, that is enclosed by a metal sheath. the first performance of the flux at the core of the wire is to supply shielding of the arc from oxidizing gases within the atmosphere like atomic numbers 8 and N.

The metal sheath accounts for seventy-five to ninetieth of the wire's weight.

For some FCAW electrodes, supplemental shielding is

additionally provided within the sort of shielding gas. The composition of

the wire, the flux within the core, and the shielding gas verify the

ultimate chemical and mechanical properties of the weld metal deposited on that

wire.

A typical wire employed in the FCAW method is shown in

Figure one below. For steel electrodes, the flux at the core solely serves to

defend the arc.

In some low alloy electrodes, the flux conjointly is a vehicle

for the distribution of bound alloying components. Some metal powders square

measure others to fluxes as additives. These metals square measure other than the

weld metal, therefore rising its properties.

In this article, we'll shortly discuss the functions of flux

parts in very few wires and the way to classify totally different flux-cored

wires. Next, a brief introduction to the varied grades of few wires offered

within the marketplace for steel, low-alloy steel, and stainless-steel base

metals is roofed.

Functions of flux material in the core

The role performed by the flux core in FCAW wire is

primarily performed by flux-covering in a very secure metal arc conductor. a

number of these tasks square measured as follows:

It contains components that induce the formation of dross on

the liquified weld metal. mold deposits choose high metal, and defend

the solid metal from oxidization by regional gases.

Flux contains oxidizers like chemical elements, Mn, etc that

facilitate purifying the liquified metal, and free it from atomic number 8.

Flux has arc stabilizers that stabilize the arc, so a swish

operation may be achieved. a gradual arc provides less splash.

Flux can even be used as a vehicle for the delivery of bound

alloying components to the welded metal. This reduces the requirement for these

components to return through the wire. the required chemical will therefore be

obtained through the flow route instead of wishing on the wire. this permits the sourcing of wire simply and cheaply.

Classification of Flux-Cored Electrodes

The system of classification of FCAW wires was 1st devised

by the Yankee fastening Society. ASME has conjointly adopted an equivalent

system. In ASME Section II, half C - FCAW electrodes square measure classified

beneath SFA five.20, SFA 5.22, SFA 5.29, SFA 5.34, and SFA 5.36 for varied

grades of base metals.

For steel electrodes for flux-cored arc fastening, the classification of electrodes is in keeping with the subsequent factors. this

method is outlined in SFA five.20. Similar system is followed for different

grades conjointly. These factors are:

Tensile strength of the weld metal.

welding position.

Utility characteristics of electrodes.

Type of shielding gas.

Carbon Steel Flux-Cored Arc fastening conductor

Carbon steel electrodes for flux-cored arc fastening square

measure bunchy beneath specification SFA five.20 of ASME Section II half

C. a brand new ASME code version comes out every 2 years. However, the system of

classification of those electrodes has remained equivalent for many years.

E70T-4 could be an unremarkably used classification of steel

FCAW electrodes. let's have a look at what every range suggests.

The letter 'E' indicates that it's AN conductor.

The number '7' indicates the strength of the weld metal

deposited by this conductor, once deposited in keeping with the tactic outlined

in SFA five.20. '7' indicates that the strength is seventy ksi (or 70000 psi).

AN '8' would indicate eighty ksi, and so on. The mechanical properties of the

various classifications square measured given in Table one below.

The third digit is either '0' or '1'. '0' indicates that the

conductor is appropriate to be used in flat and horizontal positions. A '1'

indicates that the conductor is appropriate for all conditions.

The letter 'T' within the fourth position indicates that the

conductor could be a flux-cored arc-fastening conductor. The 'T' stands for a

cannular conductor, which suggests that the conductor is sort of a tube.

The number in fifth place is the digit from one to

fourteen. this is often the utility designation and indicates the quality of

the conductor together with the necessities for polarity and traditional operation characteristics. If a 'G' seems at this location, it indicates that

the polarity and traditional operation characteristics don't seem to be

outlined. The utility characteristics of various classifications square measured

shown within the table below.

If AN 'S' seems once this digit, it indicates that the wire

is appropriate for single-pass fastening solely.

The mechanical properties of steel flux-cored arc fastening

electrodes may be found in Table one in SFA five.20 of ASME Section II half C.

C . utility characteristics of

Urban steel flux-cored arc fastening electrodes may be found

in Table a pair of SFA five.20 of ASME Section II C.

Low steel Flux-cored Arc manner landing conductor

The system of classification of low steel electrodes for

flux-cored arc fastening is outlined in SFA five.29 of ASME Section II half C.

The system is analogous to it a steel conductor. allow us to perceive

through AN example. E81T1-Ni2 could be an unremarkably used LAS FCAW conductor.

let's have a look at what every range suggests.

0 Comments

Leave a Reply...